When it comes to construction or renovation projects that require a reliable and strong fastening solution, choosing the right hardware is crucial. Among the various options available, concrete screws have emerged as the preferred choice for professionals and DIY enthusiasts alike. In this article, we explore why concrete screws are the go-to choice for heavy-duty installations and what makes them stand out in demanding applications.

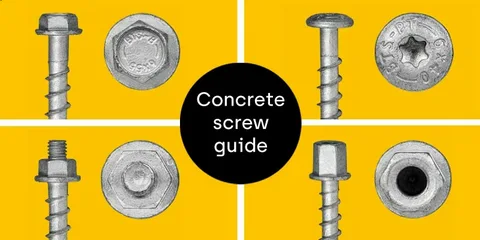

Understanding Concrete Screws

Concrete screws are specially designed fasteners that can anchor materials directly into concrete, masonry, or brick without the need for anchors or adhesives. Unlike traditional nails or regular screws, concrete screws create a tight, secure hold by cutting threads directly into the material. This unique feature ensures that the fastener maintains its strength even under significant stress.

Advantages of Using Concrete Screws

- High Load-Bearing Capacity

One of the main reasons why concrete screws are the go-to choice for heavy-duty installations is their impressive load-bearing capacity. Whether you are installing heavy shelving units, handrails, or structural supports, these screws can handle substantial weight without loosening over time. - Ease of Installation

Unlike other anchoring methods that require pre-inserting plugs or adhesives, concrete screws are straightforward to install. A simple pre-drilled pilot hole is all that’s needed before driving the screw directly into concrete. This efficiency reduces labor time and ensures a cleaner, more professional finish. - Durability and Longevity

Concrete screws are often made from hardened steel and coated with corrosion-resistant materials, which makes them suitable for both indoor and outdoor applications. Their resilience against rust and wear contributes to long-lasting performance in challenging environments.

Ideal Applications for Concrete Screws

Concrete screws are versatile and can be used in a wide range of heavy-duty installations, including:

- Securing metal framing to concrete walls

- Mounting electrical boxes and conduit

- Installing HVAC equipment and ductwork

- Attaching shelving and storage systems

These applications demonstrate why concrete screws are the go-to choice for heavy-duty installations, as they provide a reliable solution for structural and load-bearing projects.

Tips for Choosing the Right Concrete Screw

To maximize the benefits of concrete screws, consider the following factors:

- Screw Length: Ensure the screw penetrates deep enough into the concrete for maximum holding power.

- Diameter: Thicker screws offer better load-bearing capacity for heavy-duty applications.

- Coating Material: For outdoor or moist environments, select screws with corrosion-resistant coatings to prevent rusting.

Conclusion

In summary, concrete screws are the go-to choice for heavy-duty installations because of their strength, durability, and ease of installation. From commercial construction projects to home improvement tasks, these screws provide a reliable fastening solution that can handle significant weight and stress. For anyone looking to secure materials to concrete or masonry, concrete screws remain the smart, practical, and efficient option.